Model: Ф1.2x4.5-Ф4.2x13

Capacity: 1.4-87 (t/h)

Grinding Body(t): 2-278

Application: Cement Clinker Industry

1. The finished product has high fineness and large specific surface.Compared with other enterprises in the same industry, the cement produced by our cement mill has the advantage of high fineness and large specific surface. The cement has excellent quality, high hydration reaction speed, fast strength development, and good intensity after hardening.

2. High efficiency and large output. We have rich experience on the manufacture of cement mill, and our technology take a leading place in the industry. Compared with other products in the same industry, the output increases by 15-20%, power consumption reduces by 10%. Moreover, the temperature of finished product can reduce by 10-20℃.

Cement ball mill is the main grinding equipment for finished products and raw materials in the cement factory. And it can also be used for other materials like coal, feldspar, slag, quartz, granite and so on. Ball mill of cement production is capable of dry production and also can be wet. You can simultaneously grind and dry operation.

Cement ball mill has many outstanding features, such as strong adaptability of materials to production, high grinding ratio, high quality final products and good abrasion resistance, easy operation of ajusting the grinding fineness of the product and so on. And the cement ball mill has the advantages of small investment and reliable operation.

ZK Corp as a professional cement plant machinery manufacturer, also provide complete cement production line with capacity from 100 t/d to 3000 t/d and cement clinker grinding unit with capacity from 50 t/d to 1500 t/d.

We have rich project experience in many countries, such as Indonesia, Malaysia, Vietnam, Iran, Sri Lanka, Pakistan, New Zealand, Venezuela, Bolivia, Guyana, Russia, Armenia, and many more. In addition to the complete equipment of the ball mill, we also provide ball mill spare parts according to your technical parameters: Ball mill steel balls, liner, shell, bearing, etc. Looking forward to your inquiry, we will give you professional suggestion, perfect service and best price.

.jpg)

|

Specification (m) |

Capacity (t/h) |

Rotating speed (r/min) |

Grinding body (t) |

Motor |

Reducer |

Weight (t) |

||

|---|---|---|---|---|---|---|---|---|

|

Model |

Power (kW) |

Model |

Speed ratio |

|||||

|

Φ1.2x4.5 |

1.4 |

30.3 |

5 |

YR250M-6 |

55 |

ZD30-8 |

4.481 |

13.1 |

|

Φ1.5x5.7 |

3.5 |

26.34 |

11 |

JR127-8 |

130 |

ZD40-7 |

4 |

25 |

|

Φ1.83x6.4 |

6 |

23.9 |

18 |

JR137-8 |

210 |

ZD60-8 |

4.5 |

35.3 |

|

Φ1.83x7 |

6.5 |

24.5 |

20 |

JR138-8 |

245 |

ZD60-8 |

4.5 |

37.2 |

|

Φ2x9 |

9.5-10 |

23.88 |

31 |

JR158-8 |

380 |

ZD70-8 |

4.5 |

58.4 |

|

Φ2.2x6.5 |

11 |

21.4 |

30 |

JRQ158-8/YR630-8 |

380 |

ZD70-9 |

5 |

46.2 |

|

Φ2.2x6.5 |

14 Closed circuit |

21.4 |

30 |

JRQ158-8/YR630-8 |

380 |

ZD70-9 |

5 |

46.2 |

|

Φ2.2x7 |

12 |

21.4 |

30 |

JR158-8 |

380 |

ZD70-9 |

5 |

54 |

|

Φ2.2x7.5 |

13 |

21.4 |

32 |

JR158-8 |

380 |

ZD70-9 |

5 |

63 |

|

Φ2.2x8 |

14 |

21.4 |

37 |

JR158-8 |

380 |

ZD70-9 |

5 |

65 |

|

Φ2.2x9.5 |

14-16 Closed circuit |

21.4 |

43 |

JR1510-8 |

475 |

ZD70-9 |

5 |

70 |

|

Φ2.2x13 |

16 |

20.3 |

55 |

YR630-8/1180/Y100L-8 |

630/11 |

JD630/ZS82.5-7 |

6.3/99.96 |

114.4 |

|

Φ2.4x7 |

14-16 Closed circuit |

20.4 |

36 |

JR1510-8 |

475 |

JDX450 |

5 |

67.9 |

|

02.4x8 |

16-17 Closed circuit |

20.3 |

41 |

JR1512-8/Y180L-8 |

570/11 |

JD630/ZS82.5-7 |

6.333/99.96 |

87.2 |

|

Φ2.4x9 |

17-19 Closed circuit |

20.3 |

46 |

YR630-8/1180/Y100L-8 |

630/11 |

JD630/ZS82.5-7 |

6.333/99.96 |

93.5 |

|

Φ2.4x10 |

18-19 Open circuit |

20.3 |

50 |

YR630-8/1180/Y100L-8 |

630/11 |

JD630/ZS82.5-7 |

6.333/99.96 |

99.4 |

|

Φ2.4x11 |

19-21 Open circuit |

20.3 |

60 |

YR630-8/1180/Y100L-8 |

630/11 |

JD630/ZS82.5-7 |

6.333/99.96 |

99.4 |

|

Φ2.4x12 |

25-27 Closed circuit |

20.3 |

61 |

YR800-8/1180/Y100L-8 |

800/11 |

JD630/ZS82.5-7 |

6.333/99.96 |

112.7 |

|

Φ2.4x13 |

25-27 High fine open circuit |

20.3 |

66 |

YR800-8/1180/Y100L-8 |

800/11 |

JD630/ZS82.5-7 |

6.333/99.96 |

131.1 |

|

Φ2.4x13 |

21-23 Open circuit |

20.3 |

66 |

YR1000-8/1180/Y160M-4 |

1000/11 |

JD630/ZS82.5-7 |

6.333/99.96 |

130.4 |

|

Φ2.6x10 |

25-27 Closed circuit |

20.3 |

60 |

YR800-8/1250 |

800 |

JD800 |

5.5 |

150.5 |

|

Φ2.6x13 |

27-29 |

19.1 |

80 |

YR1000-8/1180/Y160M-4 |

1000/11 |

|

5.5/280 |

169 |

|

Φ3x9 |

33-34 Closed circuit |

19.6 |

79 |

YR1000-8/1180/Y160M-4 |

1000/11 |

NAL108/8/ZS110-19 |

8/280 |

156.5 |

|

Φ3x11 |

35-40 Closed circuit |

18.3 |

97 |

YR1250-8/1430/YR160M-4 |

1250/11 |

YNL1210 |

6.3 |

178 |

|

Φ3x11 |

47 Closed circuit |

17.7 |

97 |

YR118/74-8 |

1250 |

ZI314 |

42.39 |

169 |

|

Φ3x12 |

38-40 Closed circuit |

18.1 |

90 |

YR1250-8/1430 |

1250/11 |

JS1100-00 |

41.27 |

196.26 |

|

Φ3.2x11 |

40 Closed circuit |

18 |

103 |

YR1400-8/1430/Y160M-4 |

1400/11 |

YNL1210/ZS110-19 |

12.35/28 |

186.1 Without motor |

|

Φ3.5x11.5 |

65-70 Closed circuit |

16.5 |

129 |

TYD143/49-8 |

2000 |

ZI370 |

36.239 |

138.3 Without motor |

|

Φ3.5x11.5 |

50 Closed circuit |

17.2 |

126 |

YR1800-8/1430/Y200L2-2 |

1800/37 |

|

43.02/318 |

252.27 |

|

Φ3.8x13 Double slipper |

70-75 Closed circuit |

16.6 |

170 |

YRKK800-8 |

2500 |

JS130/MFY250 |

44.9 |

203 Without motor |

|

Φ3.8x13 |

60-62 |

16.3 |

170 |

YR2500-10/1730 |

2500 |

MFYX250 |

|

286 |

|

Φ4x13 |

65 Closed circuit |

15.95 |

202 |

YRKK900-8 |

2800 |

JS130-8 |

46.7 |

264 |

|

Φ4.2x13 |

85 Closed circuit |

16.3 |

224 |

YRKK900-8 |

3150 |

MFY320 |

47.8 |

250 Without motor |

|

Φ4.2x13 |

85-87 |

16.3 |

224 |

YR1000-8 |

3530 |

JQS3550 |

15.6 |

254 Without motor |

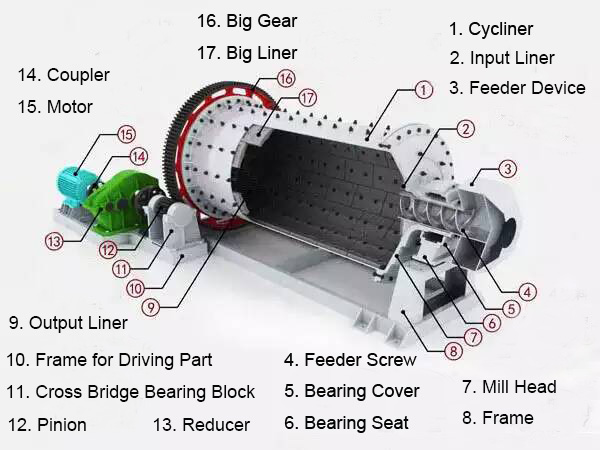

Cement ball mill is mainly consisting of feeding device, big gear, discharge device, cylinder, diaphragm plate, hollow shaft, liner, drive device and other components.

Please input your inquiry in below form. We will reply you as soon as possible!