Model: 900*900 --1200*2400

Rotary speed: 40-36 (r/min)

Discharging size: 0.075-0.4 (mm)

Weight: 4.5-12 (t)

1. Liner of ball mill is made of high-quality wear resistant material with high strength, wear resistance and long working life.

2. Product fineness is adjustable, uniform and high qualified.

3. Large capacity and crushing ratio, good sealing performance. It can be adapted to different working conditions.

4. High grinding efficiency, low energy consumption

Horizontal Ball Mill is widely used for grinding in mining (metallic minerals and non-metallic minerals), cement, refractories, chemical, power plant, aluminum, building material, glass, ceramic, steel slag and fly ash, ect. It follows more crushing and less grinding principle to save energy. The feed size to ball mill shall be smaller than 25mm, the output size can be adjusted by revising steel balls ratio.

Applied materials: steel slag, white ash, gold ore, iron ore, zinc ore, cooper ore, molybdenite, quartz, bauxite, manganese, tungsten, marble, granite,bluestone, kaolin, spodumene, mica, calcite, fluorite, magnesite, aluminum powder, quartz sand, aluminum powder paste, hematite, Iron concentrate, fluorite ore, barite, potash feldspar, tungsten carbide, barite, clinker, slag, bauxite, etc.

|

Model |

Rotary speed (r/min) |

Ball loading(t ) |

Feed size (mm) |

Discharging size (mm) |

Output capacity (t/h) |

Motor power (kw) |

Weight (t) |

|

900*900 |

40 |

0.67 |

0-20 |

0.074-0.6 |

0.23-0.74 |

15 |

4.5 |

|

900*1800 |

38 |

1.5 |

0-15 |

0.075-0.8 |

0.3-0.8 |

y11- 4 |

3.8 |

|

900*2100 |

38 |

2.0 |

0-15 |

0.075-0.8 |

0.5-1.3 |

y15-4 |

5.6 |

|

900*3000 |

36 |

2.7 |

0-20 |

0.075-0.8 |

1.1-3.5 |

22 |

|

|

1200*2400 |

36 |

3 |

0-20 |

0.075-0.6 |

1.5-4.8 |

30 |

12 |

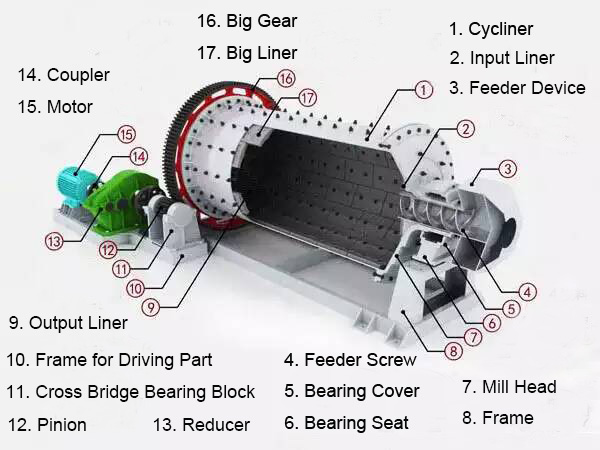

The Ball Mill is a horizontal rotary drum apparatus driven by gears outside. It is a lattice pattern with two storage cells. The raw materials enter into the first cell of the Ball Mill evenly through the quill shaft in charging part. There are step liner palates or wave liner palates in the first cell which have been loaded various steel spheres of different scales. When rotating, the drum causes centrifugal force that brings the steel spheres to a certain height and then the spheres drop to impact and grind the materials. After the rough grinding in the first cell, the qualified partials will enter into the second cell through a single division plate .There are flat palates welded on the inner wall of the second cell, as well as steel spheres. The materials will be further grinded in it and at last the qualified granularities will be discharged through the unload part. Then the whole process is completed.

Please input your inquiry in below form. We will reply you as soon as possible!