Volume(m³/h): 67300-314000

Filtration area(㎡): 935-4361

Net filtration area(㎡): 4205

Dust content at inlet(g/m³): <1300

1. New and advanced dust removing concept. No air pipe. Pulse valve is assembled at the side the chamber shell or top. No need to disassemble and assemble the air pipe when replacing the bags.

2. High performance pulse is applied to replace many smaller pulse to reduce the maintenance as much as possible.

3. Multi-chamber and off-line dust removing. Long life of filter bag.

4. Available for high density dust containing air collection, for example, O-Sepa separator, the dust content of which will reach 1000g/Nm3.

5. Air tank will reduce the pressure decrease caused by equipment.

With high cleaning efficiency, PPC Series Pulse Jet Bag Filter incorporates the advantages of other bag filters as compartmental blow-back, pulse jet cleaning. It overcomes disadvantages of weak cleaning strength of blow-back as well as synchronous working of pulse jet cleaning and filtering, expaning the field of application, it is featured with strong cleaning strength, high effective, long life. It is suitable to the treatment of high concentration dust, simplifying the technical process of dust treatment and reducing investment of device.

Application:

This series of bag filter is widely used in cement, metallurgy, machinery, chemical and refractory industries, especially for dust collectiom system, such as crushing, packaging, warehouse, clinker cooler and various grinding mill in cement plant. In additon, it can be used in dust collection of coal mill. However, in the dust collection of ball mill, anti-explosion equipment should be added and related struture changed.

According to different Bag Quantity, Plenum Pulse Dust collector could be classified as 32bags/room, 64bags/room,96bags/room,128bags/room. Each kind will be divided into many different type-33 kinds in total.

| Model | PPC96-4 | PPC96-5 | PPC96-6 | PPC96-7 | PPC96-8 | PPC96-9 |

PPC96- 2×5 |

PPC96- 2×6 |

PPC96- 2×7 |

PPC96- 2×8 |

PPC96- 2×9 |

PPC96- 2×10 |

|

| Air volume (m³/h) | 26800 | 33400 | 40100 | 46800 | 53510 | 60100 | 66900 | 80700 | 94100 | 107600 | 121000 | 134500 | |

| Air speed (m/min) | 1.2~2.0(Filtering speed should be determined by different dust collecting location) | ||||||||||||

| Total filtering area (m²) | 372 | 465 | 557 | 650 | 744 | 836 | 929 | 1121 | 1308 | 1494 | 1681 | 1868 | |

| Net filtering area (m²) | 279 | 372 | 465 | 557 | 657 | 744 | 836 | 1028 | 1215 | 1401 | 1588 | 1775 | |

| Qty of bag(pc) | 384 | 480 | 576 | 672 | 768 | 864 | 960 | 1152 | 1344 | 1536 | 1728 | 1920 | |

| Pressure drop (Pa) | 1470~1770 | ||||||||||||

| Negative pressure (Pa) | 5000 | ||||||||||||

| Inlet dust concentration (g/m³) | < 1300 | ||||||||||||

| Outlet dust concentration (mg/m³) | ≤30 | ||||||||||||

| Air cleaning compressed ain | Pressure (MPa) | 0.5~07 | |||||||||||

| Consumption (m³/min) | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3 | 3.4 | 4.2 | 4.8 | 5.4 | 6 | |

| Pulse valve | Qty(pc) | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 12 | 14 | 16 | 18 | 20 |

| Size(inch) | 2~1/2” | ||||||||||||

| Lift valve (with cylinder) | Qty(pc) | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 12 | 14 | 16 | 18 | 20 |

| Size (mm) | Dia.Of lift valve:Φ725,Dia.Of cylinder:φ100 | ||||||||||||

| Rotary discharger YJD-26 | Outlet:400×400,Rev.speed:45r/min,Power of reducer:2.2kW,Capacity:72.2m³/h 1 set for single row,2 sets for double row. | ||||||||||||

| Screw conveyor | Specification | Dia.:Φ400,Capacity:38m³/h,1 set for single row,2 sets for double row. | |||||||||||

| Reducer | Model:XWD5.5-7-1/59,power:5.5kW | ||||||||||||

| Air slide | If the inlet dust concentration is more than 700g/m³,the bag fiterwith air slide or big size screw conveyor should be selected. | ||||||||||||

| Size and material of bags | Dia.×L:Φ130×2450mm,Gross weight of polyester needle-felt:450g/m²,working temp.:120℃ | ||||||||||||

| Area of insulating layer(m²) | 110 | 120 | 130 | 140 | 150 | 160 | 175 | 210 | 245 | 280 | 315 | 350 | |

| Total weight (approx.)(kg) | 11290 | 13100 | 16070 | 18270 | 20350 | 22940 | 27220 | 32660 | 38100 | 43540 | 48990 | 54430 | |

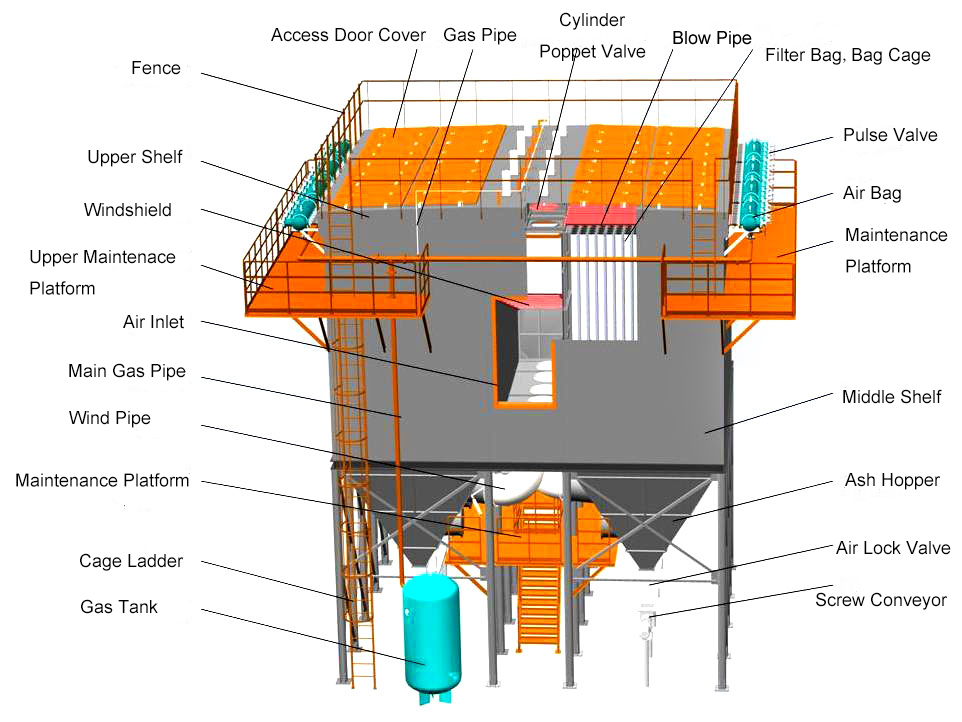

Pulse Jet Bag Filter consists of upper chamber, middle chamber, dust hopper, air inlet and air outlet, as well as support, cage, handrail, air blow system, control system and discharge device.

1. The upper chamber is divided into several rooms, each of which is equipped with a valve to enable off-line dust removing.

2. The middle chamber is divided into several rooms to avoid mutual influence during dust removing.

3. Chamber shell is made of high strength steel.

Please input your inquiry in below form. We will reply you as soon as possible!