Capacity: 15 (t/d)

Granulator: Φ2.8×5 (m)

Mesh Belt Dryer: DW1.6×16 (m)

Rotary Kiln: Φ1×18 (m)

1. High degree of automation: It avoids the impact of artificial factors on the quality of molecular sieve products, and the quality of the products produced is excellent. The quality of all granular products is basically the same, and the phenomenon of uneven defective products is avoided;

2. The on-site environment is good: the granulator uses automatic powder addition during the pelletizing process, and is equipped with a dust removal port to prevent dust from overflowing, and the on-site working conditions are good;

3. High yield: the resulting low scrap rate of molecular sieve semi-finished balls;

4. High control accuracy: powder replenishment and water addition are all accurately measured, and the measurement accuracy is within ±1% to ensure product quality.

Molecular sieve is an aluminosilicate compound with a cubic lattice. Molecular sieve has a uniform microporous structure, and its pores have uniform diameters. These pores can adsorb molecules smaller than their diameter into the interior of the pore cavity, and have preferential adsorption capacity for polar molecules and unsaturated molecules, so they can absorb polar molecules. It separates molecules with different degrees of sex, different degrees of saturation, different molecular sizes and different boiling points, that is, it has the function of "sieving" molecules, so it is called molecular sieve.

Application:

It can be used as desiccant, selective adsorbent, catalyst, ion exchanger, etc. in chemical industry, metallurgy, building materials, mining and other industries.

|

Product |

Capacity(t/d) |

Production Capacity |

||

|---|---|---|---|---|

|

Modecular Sieve |

15 |

Granulator:Φ2.8×5m |

Mesh Belt Dryer:DW1.6×16m |

Externally Heated Rotary Dryer:Φ1×18m |

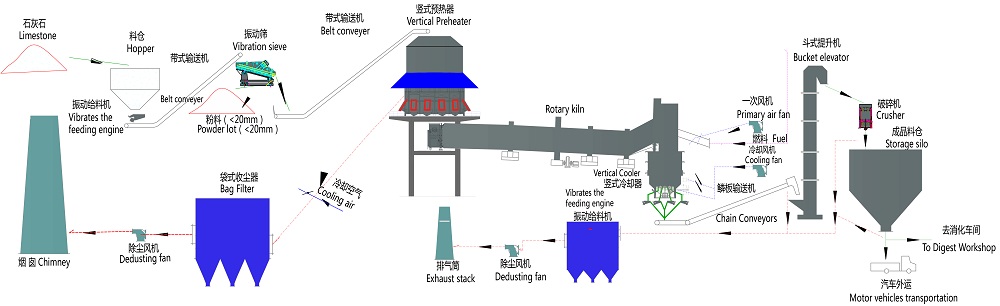

1. Mixing

Send several raw materials for making molecular sieves into the ribbon mixer according to the set ratio and mix them evenly. After mixing, they are sent to the buffer bin through a screw conveyor and a bucket elevator;

2. Granulation

After measurement by the spiral weighing scale installed under the cache bin, the material is sent to the granulator's spiral feed inlet through the bucket elevator, and the set water is added to the granulator through the water metering device. The material and water The granulator is fully contacted to form a ball. The inside of the granulator is equipped with a scraper and a rake device, which can prevent the material from bonding to the inner wall. The rake can effectively prevent the material from forming agglomerates. Part of the material formed by the granulator is sent to the two-stage vibrating screen for screening, and part is sent back to the granulator through the return belt conveyor and bucket elevator for recycling granulation;

3. Hardening

Qualified materials are hardened through the hardening cylinder to make the surface of the material more rounded and the quality of the finished product to be better;

4. Drying

Dry the shaped materials through a mesh belt dryer. Mesh belt drying is static drying, which can reduce the breakage of the material balls;

5. Calcining

The dried pellets are calcined through an externally heated rotary kiln. The externally heated rotary kiln avoids direct contact between the material and the hot flue gas, which can reduce pollution to the material;

6. Screening and packaging

The calcined materials are screened through a rotary vibrating screen and then sent to the finished product warehouse. There is a packaging machine under the warehouse, and the materials can be packaged into appropriate specifications through the packaging machine.

Please input your inquiry in below form. We will reply you as soon as possible!