Volume(m³/h): 6000 -54000(m³/h)

Filter area: 100-450(m2)

Bag size: 100-200(mm)

Cleaning mode: on-line ash cleaning

1. Reliable design ensures the bag filter dust collector stable and long-term operation with the other main equipment and little maintenance.

2. Optimized duct design will be in favor of uniform air distribution.

3. Air leakage prevention design ensures the lowest air leak rate for the bag filter.

4. Steel sub-structure design, which would be easy for transport and installation of the equipment.

5. Low operating costs. Optimized design of process parameters is conducive to efficient and stable operation of the bag filter with low resistance, reducing energy consumption, as well as the loss of the bag.

Bag filter dust collector system is a kind of dry dust filtration device. It is used for Cement Plant, Lime Factory, Coal Powder Preparation Unit, etc. It has the features like bigger air volume, stronger dust cleaning ability, high efficiency, easy operation and maintenance and etc.

Our company can provide tailored design, manufacture, and installation one-stop service for bag-type dust collector systems. Our product range mainly includes bag filters, single bag filters, pulse bag filters, mechanical reverse air bag filters, wet bag filters, and bag filter spare parts (filter bags, bag cages, pulse valves, star-shaped dischargers, screw conveyors, etc).

|

Specification |

Air volume (m3/h) |

Air speed (m/min) |

Filter area (m2) |

Pressure drop (Pa) |

Bag size (mm) |

Bag qty (piece) |

temperature resistance (℃) |

Cleaning mode |

Weight (t) |

|

ZM100 |

6000-7000 |

1-1.2 |

100 |

1200 |

Ф130 |

100 |

<230℃ |

on-line ash cleaning |

3.6 |

|

ZM120 |

7200-8640 |

1-1.2 |

120 |

1200 |

Ф130 |

100 |

<230℃ |

on-line ash cleaning |

4.3 |

|

ZM150 |

9000-10800 |

1-1.2 |

150 |

1200 |

Ф130 |

100 |

<230℃ |

on-line ash cleaning |

5.7 |

|

ZM200 |

12000-14400 |

1-1.2 |

200 |

1200 |

Ф130 |

200 |

<230℃ |

on-line ash cleaning |

7.3 |

|

ZM250 |

15000-18000 |

1-1.2 |

250 |

1200 |

Ф130 |

200 |

<230℃ |

on-line ash cleaning |

8.8 |

|

ZM300 |

18000-36000 |

1-1.5 |

300 |

1200 |

Ф130 |

200 |

<230℃ |

on-line ash cleaning |

11.2 |

|

ZM350 |

21000-42000 |

1-1.5 |

350 |

1200 |

Ф130 |

200 |

<230℃ |

on-line ash cleaning |

13.3 |

|

ZM400 |

24000-48000 |

1-1.5 |

400 |

1200 |

Ф130 |

200 |

<230℃ |

on-line ash cleaning |

15.5 |

|

ZM450 |

27000-54000 |

1-1.5 |

450 |

1200 |

Ф130 |

200 |

<230℃ |

on-line ash cleaning |

18.9 |

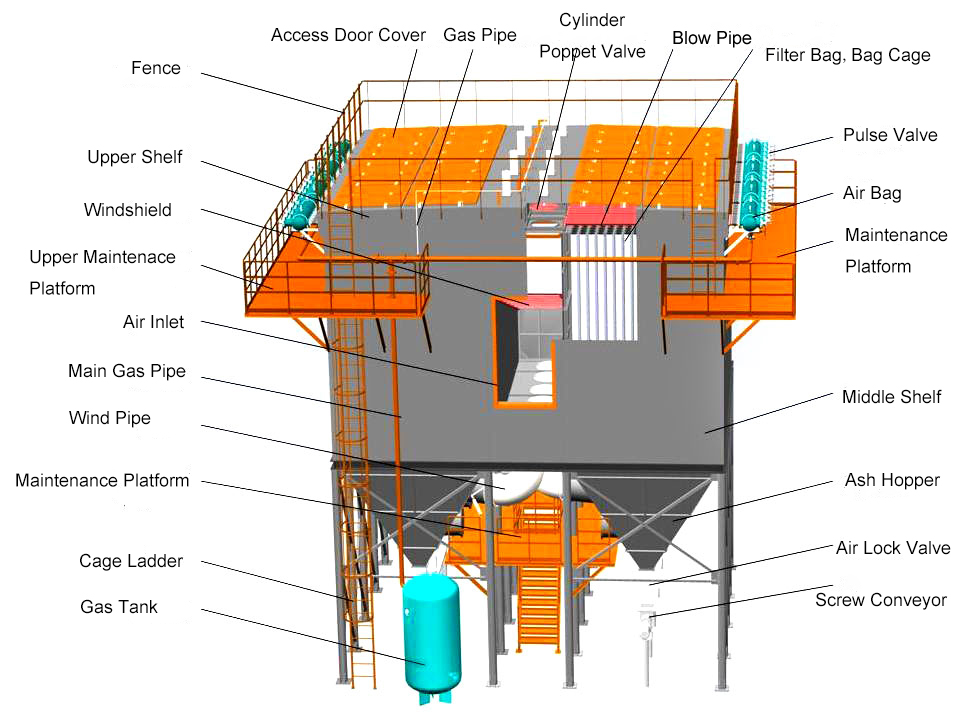

Bag filter dust collector is consist of holder, ash bucket, the middle cabinet, the upper part cabinet, bag, frame, jet cleaning device and PLC control procedures and other components. The middle cabinet has sub-chamber structure. Dusty gas goes through collecting tube achieving to each ash bucket.

Please input your inquiry in below form. We will reply you as soon as possible!