Phosphogypsum mainly comes from the production process of wet phosphoric acid and is one of the main wastes of the phosphorus chemical industry. The random discharge and storage of phosphogypsum has seriously damaged the ecological environment, not only polluting groundwater resources, but also causing waste of land resources. China has established a series of laws and policies to regulate the treatment and utilization of phosphogypsum, requiring enterprises to treat and utilize it and not to discharge it at will. These pol i c ies have promoted the development and appl i cation of comprehensive utilization technology of phosphogypsum. Disposed phosphogypsum can be used in many fields such as agriculture, building materials, environmental governance, ceramics and daily chemicals.

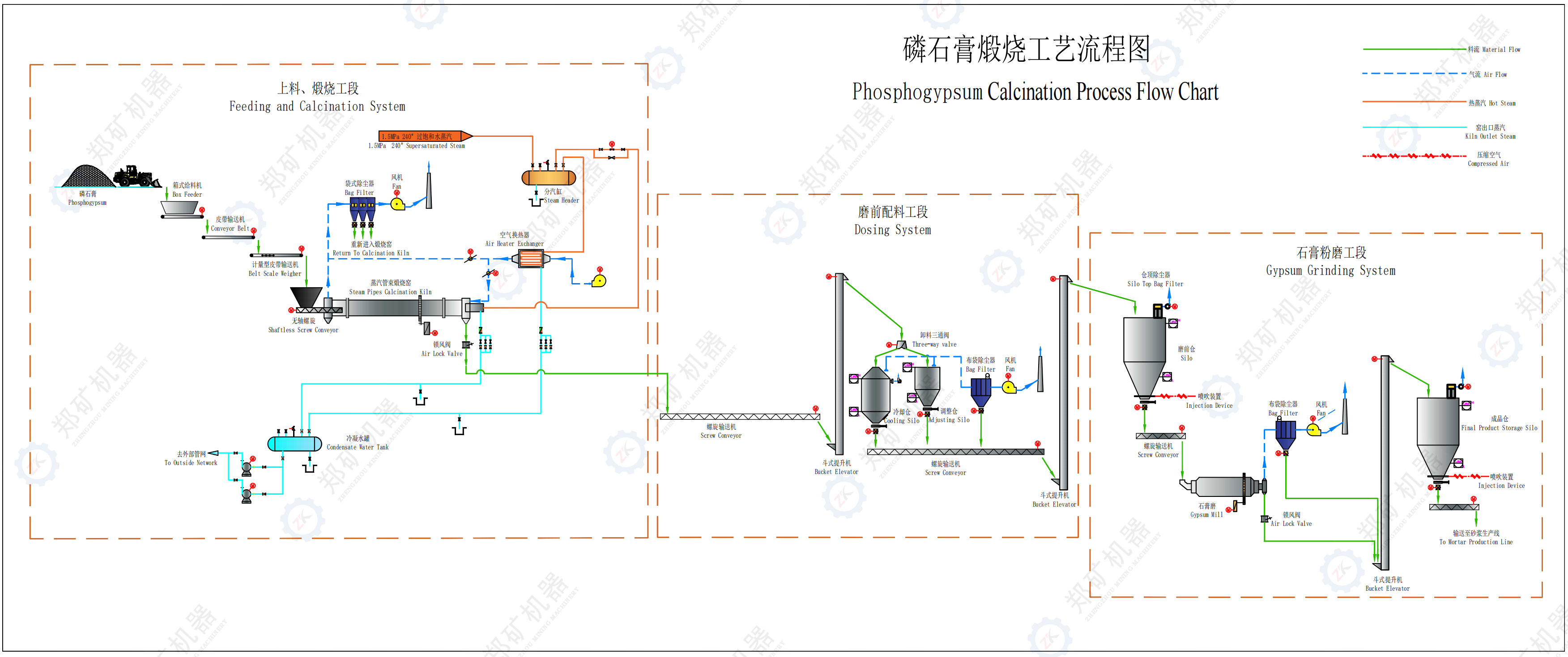

(1) Feeding & Calcining System

Phosphogypsum is loaded to the box feeder by a forklift, and then conveyed to the steam tube calcining kiln by a belt conveyor, a metering belt, and a shaftless screw. It is calcined with supersaturated water vapor at 240℃. The calcined product goes to the grinding system, and the exhaust gas is discharged into the atmosphere through the exhaust fan chimney after dust removal by a bag dust collector.

(2) Dosing System

The calcined material is sent to the cooling bin and the adjustment bin by a screw conveyor and a bucket elevator. A variable frequency feeding device is installed under the bin. After adjusting the proportion, it is sent to the pre-grinding bin by a screw conveyor and a bucket elevator.

(3) Gypsum Grinding System

A variable frequency unloading device is installed under the pre-grinding bin. The gypsum powder is sent to the gypsum mill by a screw conveyor. The ground material is sent to the finished product bin by a bucket elevator. A discharging screw is installed under the finished product bin. A packaging machine can be installed for packaging and sale, or the powdered material can be directly transported and sold in bulk by a truck.

If you are interested in our product design, specification, spare

parts, quotation etc, please feel free to contact us by WhatsApp

+8615738871677, or email us at

ec22@zkcorp.com.