Model: ZSG1237 -- 2ZSG1860

Sieve layer: 1 - 4

Feeding size: ≤ 300 (mm)

Capacity: 10 - 600 (t/h)

1. It has unique design for the screen, and is easy and fast to change screen(only need 3-5minutes), plus, this design allows to use every kind of screen(nylon, special type nylon and PP net).

2. It is ingenious and easy for assembling, one person can operate the vibrating screen.

3. Compared with other brands, it has larger sieving area and high processing capacity with high efficiency.

4. High degree of standardization, smooth and reliable operation; Large capacity, high strength, stable and reliable performance; Reasonable structural strength, high stiffness, serialization, generic.

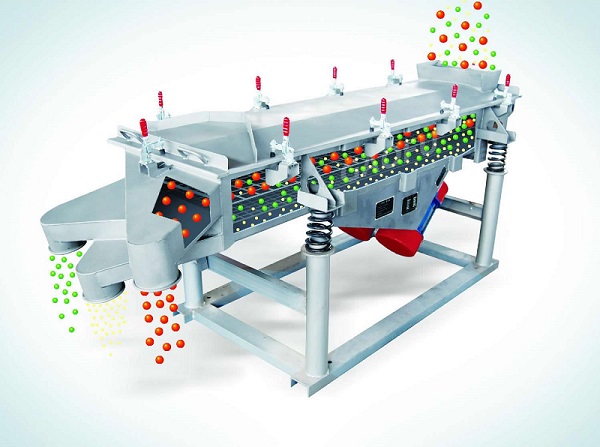

ZK series linear vibrating screen is based on the needs of China's production in the digestion and absorption shaker from abroad on the basis of summing up of our years of research experience in the design and use, combined with the national conditions , China developed this new series of vibrating screen.

Through years of practice, that the series of machine has to deal with a large amount of technical parameters of a reasonable structural strength, high stiffness, serialization, generic, and a high degree of standardization, smooth and reliable operation, low noise, maintenance overhaul to facilitate a series of advantages

Linear vibrating screen can screen and classify powder and granular material. It is applied widely in plastics, abrasives, chemicals, pharmaceuticals, building materials, food, carbon, fertilizer and other industries.

|

Model |

Sieve |

Sieve layer |

Mesh |

Feeding size |

Cap-acity |

Motor Power |

Total |

Vibr-ating frequ-ency |

Double ampl- |

Sieve |

Dimensions |

|

(L*W)(mm) |

Layer |

mm |

mm |

(t/h) |

kw |

kg |

(Hz) |

(mm) |

o |

L*W*H(mm) |

|

|

ZSG1237 |

3700*1200 |

1 |

4-50 |

<=200 |

10-100 |

5.5*2 |

2250 |

16 |

6-8 |

15 |

3800*2050*1920 |

|

2ZSG1237 |

3700*1200 |

2 |

4-50 |

<=200 |

10-100 |

5.5*2 |

3345 |

16 |

6-8 |

15 |

3800*2050*2200 |

|

ZSG1443 |

4300*1400 |

1 |

4-50 |

<=200 |

10-150 |

5.5*2 |

4100 |

16 |

6-8 |

15 |

4500*3040*2500 |

|

2ZSG1443 |

4300*1400 |

2 |

4-50 |

<=200 |

10-150 |

5.5*2 |

4900 |

16 |

6-8 |

15 |

4500*3040*2700 |

|

3ZSG1443 |

4300*1400 |

3 |

4-50 |

<=200 |

10-150 |

5.5*2 |

5870 |

16 |

6-8 |

15 |

4500*3040*2820 |

|

2ZSG1548 |

4800*1500 |

2 |

5-50 |

<=200 |

15-200 |

7.5*2 |

5836 |

16 |

8-10 |

15 |

4800*3140*2814 |

|

3ZSG1548 |

4800*1500 |

3 |

5-50 |

<=200 |

15-200 |

7.5*2 |

6900 |

16 |

8-10 |

15 |

4799*3140*3014 |

|

2ZSG1848 |

4800*1800 |

2 |

5-50 |

<=300 |

50-500 |

7.5*2 |

6489 |

16 |

8-10 |

15 |

4799*3440*2814 |

|

3ZSG1848 |

4800*1800 |

3 |

5-50 |

<=300 |

50-500 |

7.5*2 |

7750 |

16 |

8-10 |

15 |

4799*3440*3014 |

|

4ZSG1848 |

4800*1800 |

4 |

5-50 |

<=200 |

50-500 |

11*2 |

8300 |

16 |

8-10 |

15 |

4799*3440*3503 |

|

2ZSG1860 |

6000*1800 |

2 |

5-150 |

<=300 |

80-600 |

11*2 |

9950 |

16 |

8-10 |

15 |

6000*3440*3326 |

Please input your inquiry in below form. We will reply you as soon as possible!