Model: Ø1.0×10m-Ø3.6×36m

Capacity: 1-40(t/h)

Power: 11-400(kW)

Application: fertilizers, organic fertilizers, inorganic fertilizers

1. High heat efficiency

The principle of heat transfer of the cylinder dryer is heat conduction and the conducting direction keeps identical in the whole operation circle. Except heat loss of end cover and radiation loss, all heat can be used for evaporation of wet materials on the wall the cylinder. The efficiency can reach 70-80%.

2. Large operation elasticity and wide application

Various drying factors of the dryer can be adjusted, such as concentration of feeding liquid/thickness of material film, temperature of heating medium, rotating speed of the drum etc. which can change drying speed of the under dryer. As these factors have no interrelations each other, it brings great convenience to dry operation and makes it applicable to dry various materials and to meet different requirements of production.

3. Short drying period

The drying period of materials is normally 10 to 300 seconds, so it is suitable for heat-sensitive materials. It also can be pressure reducing operated if it is put in vacuum vessel.

Rotary dryer is mainly used for the drying various materials.The material inside the rotary dryer has heat exchange with the high temperature flue gas through shell rotating and material lifting by lifter. The rotary dryer has many good characters like: high efficiency, big capacity, high running rate, saving energy, easy for maintenance, long working life. Variety angle of the lifter will increase the heating exchange rate and short drying time. Feeding and discharging unit is installed with thermocouple to control drier temperature. The temperature change of drier's feeding end can be indicated by the thermometer to control the inner drier temperature (generally 250-350°C)

| Model (m) | Shell | Capacity (t/h) | Motor | Power (kW) | Reducer | |||

| Inner Diameter (mm) | Length (mm) | Slope (°) | Rev.Speed (rpm) | Motor Model | ||||

| Ø1.2X12 | 1200 | 12000 | 1.8 | 5 | 2-5 | YI60LM-6 | 11 | ZQ500 |

| Ø1.5X15 | 1500 | 15000 | 1.8 | 4.28 | 4-5 | YI60L-6 | 18.5 | ZQ650 |

| Ø1.8X18 | 1800 | 18000 | 1.8 | 5 | 6-8 | Y200LI-6 | 22 | ZQ650 |

| Ø2.0X20 | 2000 | 20000 | 2 | 3.38 | 7-10 | Y200L2-6 | 30 | ZQ650 |

| Ø2.2X22 | 2200 | 22000 | 1.8 | 2.8 | 9-14 | Y250M-6 | 45 | ZQ650 |

| Ø2.4X24 | 2400 | 24000 | 2.5 | 2.82 | 14-16 | Y280S-6 | 55 | ZQ750 |

| Ø2.8X28 | 2800 | 28000 | 2.5 | 2.55 | 20-22 | Y315S-6 | 90 | ZL115 |

| Ø3.0X30 | 3000 | 30000 | 2.5 | 2.69 | 22-24 | Y315LI-6 | 132 | ZL130 |

| Ø3.2X32 | 3200 | 32000 | 2.5 | 2.6 | 24-26 | Y315M-4 | 200 | ZSY450 |

| Ø3.6X36 | 3600 | 36000 | 2.5 | 2.51 | 30-40 | Y315L2-4 | 315 | ZL130 |

| Ø4.0X40 | 4000 | 40000 | 2.5 | 2.09 | 40-45 | YKK4003-4 | 400 | ZSY630 |

| Ø4.2X42 | 4200 | 42000 | 2.5 | 2.09 | 45-46 | YKK4005-4 | 400 | ZSY630 |

| Ø4.5X45 | 4500 | 45000 | 2.5 | 1.92 | 46-50 | YKK4502-4 | 500 | MH3S230 |

| Ø4.8X48 | 4800 | 48000 | 2.5 | 1.92 | 50-55 | YKK4504-4 | 630 | MH3S250 |

| Ø5.0X 50 | 5000 | 50000 | 2.5 | 1.92 | 55-60 | YKK4505-4 | 710 | MH3S260 |

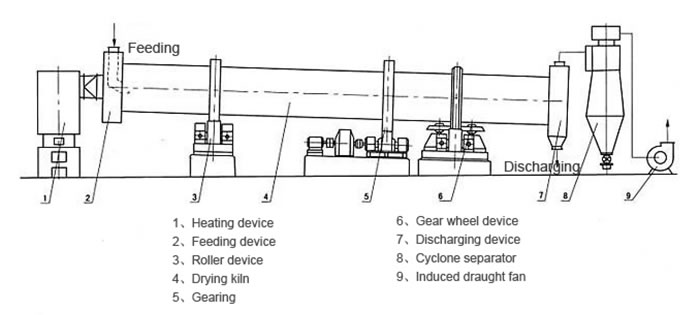

The rotary dryer is mainly composed of the rotary cylinder, the lifting plates, the transmission device, the supporting devices, the sealing ring, etc.

It is a slightly inclined cylinder, the materials are fed from the upper end against hot air, rotated together with the cylinder, the materials are moved to the lower end by gravity. In the inner wall of the cylinder the lifting plates are placed, raised and thrown again and again, increasing the contact surface between the materials and hot air, to improve the drying capacity, and to promote the movement of the materials. The dried materials are discharged through the dryer outlet.

Please input your inquiry in below form. We will reply you as soon as possible!