Max Feeding Size: 210-1020 (mm)

Capacity: 3-500 (t/h)

Inlet Size: 250×400 - 1200×1500 (mm)

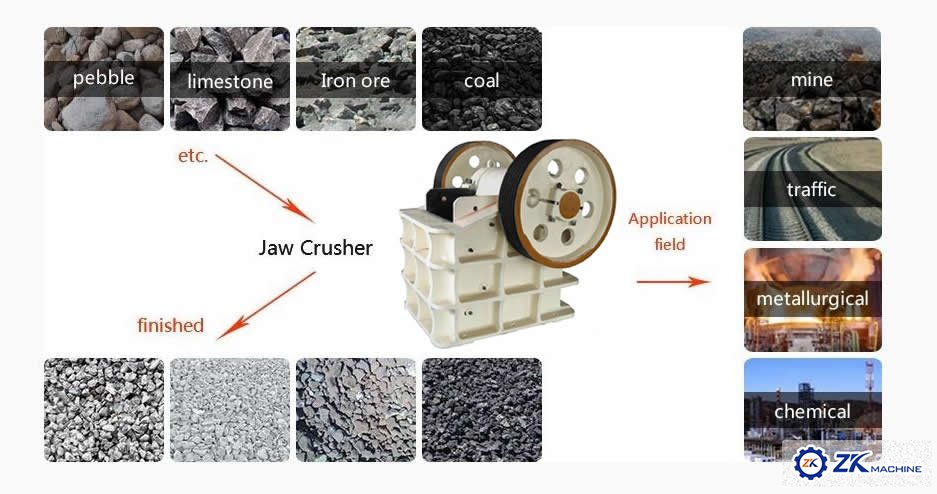

Applied Material: limestone, fly ash, quartz, iron ore, etc.

1. Jaw plates is made of high strength steel, one time shape casting, and with characteristics of wear resistant, compression resistance, and long life;

2. High productivity, large crushing ratio, uniform product size, low power consumption;

3. Gasketed discharging adjusting device, reliable and convenient, large adjustment range, equipment flexibility is increased;

4. Simple structure, reliable operation and low operating costs, safe lubrication system, and easy parts replacing.

Jaw crusher is a large kind of complex tilting crushing equipment, and it is mainly used for crushing medium hard ore and rock whose compression strength is no more than 250MPa, and with the quality of large crushing ratio, high yield, uniform particle size, reliable, easy to maintain and low operating cost.

Jaw Crusher can be used for crushing more than 100 kinds of material. it is applied in large block of material crushing in mining industry, metallurgical industry, construction industry, highway, railway, water conservancy, chemical industry and etc. PE series is used for coarse crushing different kinds of material, and PEX series is used for intermediate and fine crushing.

The price of jaw crusher depends on the model. Different models will be chosen according to your requirements such as the capacity, materials, hardness, input size and output size. As the leading manufacturer and exporter in China, we will provide maximum preferential factory price and discount for you. So please tell us your needs, and then we will reply you with the latest quotation and more information asap.

|

Model |

Inlet Size(mm) |

Max feeding size(mm) |

Adjusting Range of Discharging outlet(mm) |

Capacity(m³/h) |

Power(kW) |

Weight(t) |

|

|

PE-250×400 |

250×400 |

210 |

20~60 |

3~13 |

15 |

2.8 |

|

|

PE-400×600 |

400×600 |

340 |

40~100 |

10~35 |

30 |

6.5 |

|

|

PE-500×750 |

500×750 |

425 |

50~100 |

25~60 |

55 |

10.6 |

|

|

PE-600×900 |

600×900 |

500 |

65~180 |

30~85 |

55~75 |

15.5 |

|

|

PE-750×1060 |

750×1060 |

630 |

80~180 |

72~150 |

90~110 |

28 |

|

|

PE-800×1060 |

800×1060 |

680 |

100~200 |

85~143 |

90~110 |

30 |

|

|

PE-870×1060 |

870×1060 |

750 |

170~270 |

145~235 |

90~110 |

30.5 |

|

|

PE-900×1060 |

900×1060 |

780 |

200~290 |

170~250 |

90~110 |

31 |

|

|

PE-900×1200 |

900×1200 |

780 |

95~255 |

100~240 |

110~132 |

49 |

|

|

PE-1000×1200 |

1000×1200 |

850 |

195~280 |

190~275 |

110~132 |

51 |

|

|

PE-1200×1500 |

1200×1500 |

1020 |

150~300 |

250~500 |

160 |

100.9 |

|

|

PEX-150×500 |

150×500 |

120 |

10~40 |

3~15 |

11 |

2.5 |

|

|

PEX-150×750 |

150×750 |

120 |

10~40 |

5~16 |

18.5 |

3.5 |

|

|

PEX-250×750 |

250×750 |

210 |

15~50 |

8~35 |

30 |

5.8 |

|

|

PEX-250×1000 |

250×1000 |

210 |

15~50 |

13~45 |

37 |

6.4 |

|

|

PEX-250×1200 |

250×1200 |

210 |

15~50 |

13~50 |

37 |

7.7 |

|

|

PEX-300×1300 |

300×1300 |

250 |

15~50 |

20~60 |

75 |

11 |

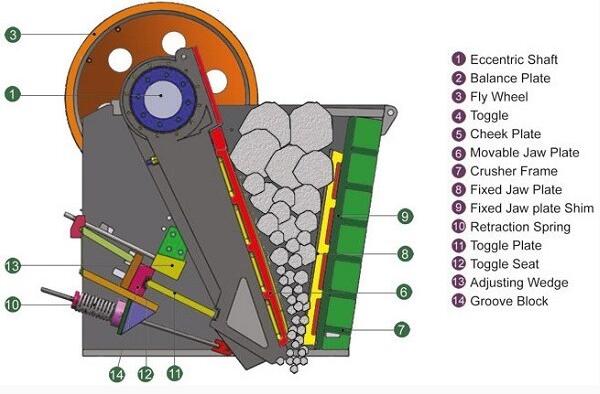

PE, PEX series jaw crusher is mainly consist of frame, eccentric shaft, pulley, side guard plate, bracket, discharging gate adjusting device, fixed jaw plate, movable jaw plate, safety device and etc. And its main structural features are as following:

1. Frame

It mainly is consist of side panels, front box assembly, rear box, and etc;

2. Eccentric Shaft Rotating Part

It mainly is consist of movable jaw, eccentric shaft, bearings, bearing pedestal, belt pulleys and etc., and it is the major part for dynamic transmission;

3. Crushing Cavity Working Part

It mainly is consist of fixed jaw plate, movable jaw plate, side liners, guard board and etc., and it is the working parts for breaking materials;

4. Safety Device

It is consist of bracket, bracket base, spring, spring rod and etc., and it is the parts that play a security role during crusher works in an abnormal condition.

5. Discharging Gate Adjusting Device

It is mainly consist of adjusting fixed ramp, adjusting sliding ramp, top wire bolt, slide locking lever, and etc., it is used to adjust the size of the discharging gate and to control the discharging particle size.

Please input your inquiry in below form. We will reply you as soon as possible!