Model: Gx150-Gx600

Max Capacity: 255.9(m³/h)

Rov. Speed: 20-90(r/min)

Conveying Material: Coal, slag, cement, clay powder, sand, grains, gravel, scrap iron etc

1. It achieved clean and environmentally friendly production, especially suitable for conveying dusty, hot (under 200 ℃) and sharp odour material.

2. The wear treated screw is more wearable and stronger than traditional common screw. It can significantly increase the service life of the screw

3. It can achieve multi-point feeding and multi-point discharging according to user's process layout.

4. The redesigned discharging structure makes the discharging smoother.

5. Compact structure, less wearing parts, convenient to install, operate and maintain.

GX Type Screw conveyor is a kind of continuous conveying equipment without flexible traction mechanism. It mainly used to convey all kinds of powdery, granular bulk materials, such as clay powder, coal, cement, sand, grains, and small lump coal, gravel, scrap iron etc. But not suitable for sticky agglomerate, perishable materials.

Screw conveyor has horizontal and inclined arragement. It can work with other conveying device to complete the concentrated transportation, distribution, agitation, mixing, dehydration, dosing, unload, stacking operation etc.

|

Model |

Screwdia (mm) |

Pitch (mm) |

Rev. Speed (r/min) |

Capacity (m³/h) |

Conveying Distance(m) |

|

GX200 |

200 |

200 |

50~90 |

7~12 |

2~15 |

|

GX250 |

250 |

200 |

45~90 |

10~20 |

2~20 |

|

GX300 |

300 |

300 |

40~80 |

15~30 |

2~20 |

|

GX400 |

400 |

300 |

35~70 |

25~55 |

2~25 |

|

GX500 |

500 |

400 |

35~65 |

45~90 |

2~25 |

|

Wearing Parts List: |

|||||

|

No. |

Name |

Quantity |

No. |

Name |

Quantity |

|

1 |

Screw Blade |

1 |

4 |

Shaft |

4 |

|

2 |

Bearing |

2 |

5 |

Transmission Shaft Coupling |

1 |

|

3 |

Nylon Pin |

8 |

6 |

Reducer Coupling |

1 |

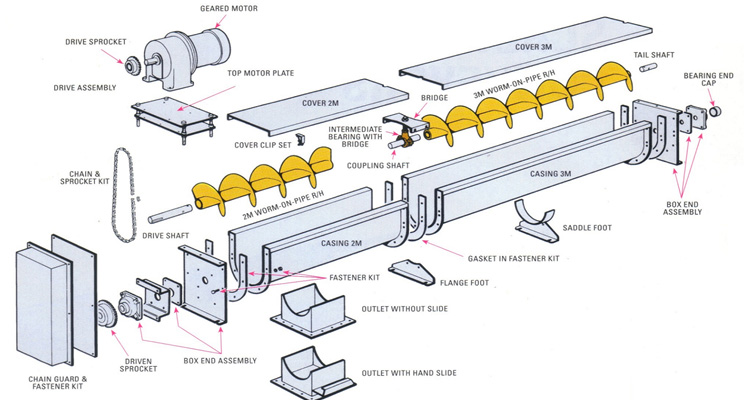

Gx series screw conveyor is mainly composed by screw, chute, hanging bearings, driver, supports, inlet and outlet. The main structural characteristics of each part are:

1.The head and tail bearing are arranged outside the chute. It avoids dust entering the bearing and convenient to install and maintain;

2.The optimized screw solved the material blocking problem at the outlet;

3.The screw shaft use reducing structure. It increases the volume at hanging bearings to reduce the wearing by the friction between bearing and material;

4.The screw shaft and hanging bearing connection applies embedded structure. There's no axial movement during mount and dismount. Thus it is convenience to maintain and repair;

5.The hanging bearing structure is compact and the dimension of axial and radial dimensions is small. It can avoid the material stuck and blocking;

6.The hanging bearing has improved sealing and lubricating structure. It help the bearing protection and lubrication effectively and can significantly increase its service life;

7.The hanging bearing is fixed at screw shaft connections of each segment. It can ensure the concentricity of the screw shaft while increasing its overall stiffness.

Please input your inquiry in below form. We will reply you as soon as possible!