Model: MBS

Capacity: 0.62 – 250 (t/h)

Feeding size: ≤25 (mm)

Applied material: ores,cement,coal,rocks, minerals

1. The discharging granularity of rod mill is evener and the output is higher.

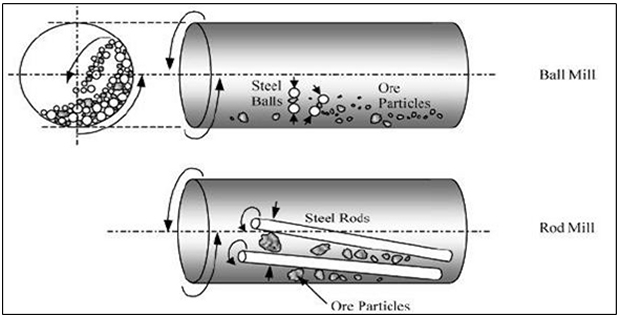

2. The grinding media contact with the ore in a linear manner, so that it has selective grinding function.

3. When used for coarse grinding, the processing amount of rod mill is higher than that of the ball mill with the same specification.

MBS series rod mill use steel rod as grinding media, it is mainly used for ore processing, suitable for non-ferrous metal and non-metallic mineral resources, compared to the general grinding equipment, the most notable feature is the steel rod in the interior of MBS type rod mill contact the material was linear, this can ensure that the equipment has a certain selective grinding effect, through MBS type rod mill grinding materials have more uniform particle size, will not appear over powder phenomenon in the process of grinding, improve the overall application value of the finished material.

Rod mill is widely applied in metal and nonmetal mine, water conservancy, glass and construction materials industries, mainly suitable for grinding various ores and rocks and artificial sand-making. Our high-efficiency rod mill adopts rolling bearing support instead of sliding bearing support with bearing bush. Therefore, it has advantages of even discharging size and high capacity.

| Model | Cylinder Diameter (mm) | Cylinder Length (mm) | Motor Model | Motor Power (kW) | Motor Rotating Speed (r/min) | Length (mm) | Width (mm) | Height (mm) | Capacity (t/h) | Effective Volume (m³) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| MBY 0918 | 900 | 1800 | Y225M-8 | 22 | 730 | 4980 | 2370 | 2020 | 0.62~3.2 | 0.9 | 5700 |

| MBY 0924 | 900 | 2400 | Y250M-8 | 30 | 730 | 5670 | 3280 | 2020 | 0.81~4.3 | 1.2 | 5880 |

| MBY 1224 | 1200 | 2400 | Y280M-8 | 45 | 730 | 6450 | 2800 | 2500 | 0.4~4.9 | 2.28 | 12308 |

| MBYg 1530 | 1500 | 3000 | JR117-8 | 80 | 725 | 7253 | 3070 | 2280 | 2.4~7.5 | 5 | 21210 |

| MBYg 2130 | 2100 | 3000 | JR136-8 | 180 | 735 | 8122 | 4220 | 3073 | 14~35 | 9 | 42123.5 |

| MBYg 2136 | 2100 | 3600 | JR137-8 | 210 | 735 | 8958 | 4320 | 3025 | 43~61 | 10.8 | 45800.5 |

| MBYg 2736 | 2700 | 3600 | JR158-8 | 380 | 743 | 10764 | 5750 | 3620 | 32~86 | 17.7 | 90441 |

| MBY 2740 | 2700 | 4000 | TDMK400-32 | 400 | 187.5 | 12300 | 5700 | 4700 | 43~110 | 20.4 | 75000 |

| MBY 3040 | 3000 | 4000 | JR1510-8 | 570 | 740 | 9800 | 3900 | 3900 | 54~135 | 26 | 90000 |

| MBY 3245 | 3200 | 4500 | TDMK800-36 | 800 | 167 | 14600 | 7000 | 5300 | 64~180 | 31 | 113000 |

| MBY 3645 | 3600 | 4500 | TDMK1250-40 | 1250 | 150 | 15200 | 8800 | 6800 | 80~230 | 41.8 | 139000 |

| MBY 3654 | 3600 | 5400 | TDMK1600-40 | 1600 | 150 | 15900 | 8800 | 6800 | 100~250 | 49.7 | 150000 |

The rod mill is a horizontal rotating device transmitted by the gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of grinding media in the chamber. The centrifugal force caused by rotation of shell brings the grinding media to a certain height and impact and grind the materials. The fine materials are discharged through the outlet, thus the grinding process is finished.

Please input your inquiry in below form. We will reply you as soon as possible!