Model : Φ750×750 - Φ1830×6400

Feed size: ≦ 20 / 25 (mm)

Capacity: 0.18-15 (t/h)

Application: Gold Ore, Iron Ore, Manganese Ore, Slag, Feldspar, Limestone, etc.

1. High grinding efficiency, low consumption; Product fineness is adjustable and uniform;

2. Low energy consumption, low wear, low operating costs; Small vibration, low noise, environmental friendly;

3. Liner is made of high-quality wear resistant material with high strength, wear resistance and long working life;

4. The hollow shaft uses steel casting, the inner lining can be dismantled and changed, and the rotary rack wheel uses casting gear hobbing and inside the cylinder there is wear-resisting lining board which has fine abrasion performance.

Ore ball mill is used to separate and screening different ore minerals, separate ore tailing. It also be used for ore grinding, non-ferrous metal beneficiation, new-type building material producing. Ore ball mill is mainly applied to the powder processing of mineral products in the industries of metallurgy, construction materials, chemical, and mining, etc.

Ore ball mill can produce powder from various non-flammable and non-explosive mineral materials with Mohs hardness below 9.3 and humidity below 6%. The product size is adjustable in the range of 80-425 mesh. Ore ball mill is possible to produce 30-80 mesh coarse powder through special device in the machine if necessary.

Applicable materials: Copper ore, iron ore, gold ore, silver ore, chrome ore, hematite ore, manganese ore, molybdenite ore, tungsten ore, barite, limestone, kaolinite and slag, etc.

| Model (mm) | Rotating Speed (r/min) | Weight of ball (t) | Inlet Size (mm) | Outlet Size (mm) | Capacity (t/h) | Motor Power (kW) | Weight (t) | Remarks |

|---|---|---|---|---|---|---|---|---|

| Φ750×750 | 40.56 | 0.5 | ≦20 | 0.074-0.3 | 0.18-0.5 | 15 | 2.774 | Energy saving mill |

| Φ900×3000 | 36 | 2.7 | ≦20 | 0.074-0.89 | 1.1-3.5 | 22 | 6.8 | Dry type |

| Φ900×3000 | 39 | 5.8 | ≦25 | 0.075-0.89 | 0.8-3.1 | 22 | 7.1 | Wet lattice |

| Φ1200×4500 | 33 | 13 | ≦25 | 0.074-0.4 | 0.7-8 | 45 | 14.2 | Wet lattice |

| Φ1500×5700 | 30 | 25 | ≦25 | 0.074-0.6 | 4-14 | 130 | 25 | Wet lattice |

| Φ1830×6400 | 24.1 | 21 | ≦25 | 0.074-0.4 | 6.5-15 | 210 | 34 | Wet overflow |

Wearing parts

| No. | Name | Material | Qty. | Part | Remarks |

|---|---|---|---|---|---|

| 1 | Spherical tile (main bearing) | HT200/ZPbSb15Sn10 | 2 | Main bearing | Different specifications, different materials |

| 2 | Cylinder liner | ZGMn13 (General) | As required | Cylinder | Different specifications, different quantities |

| 3 | Mill door liner | ZGMn13 (General) | As required | Cylinder | Different specifications, different quantities |

| 4 | Mill door (manhole cover) | ZGMn13 (General) | As required | Cylinder | Different specifications, different quantities |

| 5 | Mill door liner | ZGMn13 (General) | As required | Cylinder | Different specifications, different quantities |

| 6 | Gear | 45#Forge | 1 | Transmission device | Different requirements, different materials |

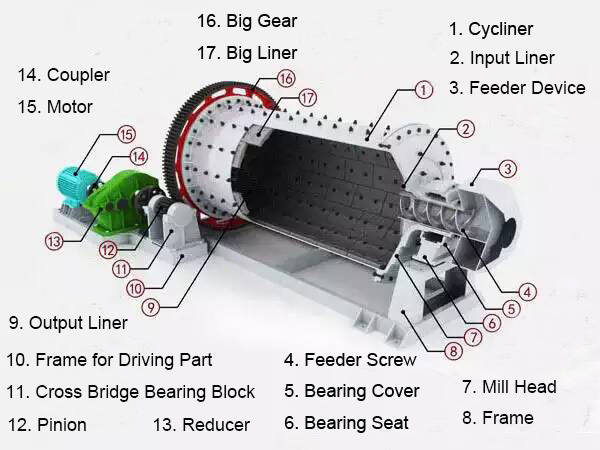

Ore Ball mill is mainly consisting of feeding device, big gear, discharge device, cylinder, diaphragm plate, hollow shaft, liner, drive device and other components.

1. The feeding device is consisting of inlet chute and screw. There are liners in the inlet chute, which can extend the working life of the feeding device.

2. There is pre-gap on the inlet hallow shaft, that can reduce the tolerance which is made of temperature changes and installation mistake to ensure the gear mesh.

3. Inside the ball mill, different parts have different liner structure, which will greatly improve the grinding efficiency.

4. Dry-type ball mill adopt sliding bearing, which is good of strength, ductility, antifriction, abrasion resistance, lubricity and thermal conductivity. It is able to meet the lubrication requirements of the hollow shaft. That is suitable for the environment of low speed and heavy load in metallurgical & ore dressing industry.

5. Wet-type ball mill adopt roller bearing, reduce useless work consumption and easy to replace.

Please input your inquiry in below form. We will reply you as soon as possible!