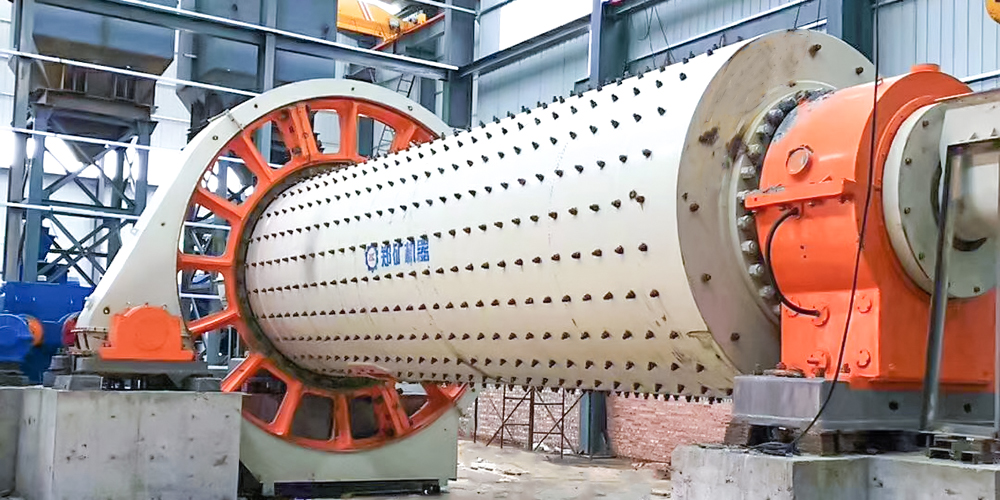

As a fine grinding machine,ball mill machine is widely used in in mining (metallic minerals and non-metallic minerals), cement, refractories, chemical, power plant, aluminum, building material, glass, ceramic, steel slag and fly ash, ect. According to the row of ore in different ways, ball mill machine can be divided into grid type and overflow type.

Ball mill machine grinds cement clinker, gypsum and similar materials of moderate moisture content in a one-compartment or two-compartment system. As the crushing compartments rotate, the balls inside them grind the clinker. Grinding ball size determines the degree of finished product fineness.

Ball mill machine can operate in an open or closed circuit and has a corrugated lining in the grinding compartment for adding effectiveness.

The ball mill machine is consisted of standard modules that can be configured for capacity, plant layout and end-product specifications. The drive can be fitted as a side or central drive upon request, and mills can be fitted with pre-grinders to achieve maximum grinding efficiency for any specified end-product quality. When fitted with the hydraulic roller press as a pre-grinder, for example, the power consumption of the whole mill system can be reduced by up to 30%.

Ball mill is easy to operate and maintain, ensuring production efficiency and high running time. A large through-flow area facilitates the flow of venting air, which ensures a low pressure drop across the mill and thus lower energy consumption.

ZK Corp produce and provide various types of ball mill,overflow ball mill,horizontal ball mill,continous ball mill,ceramic ball mill,batch ball mill,etc.

Please input your inquiry in below form. We will reply you as soon as possible!

“The first-class professional design services High quality products.”

Henan Zhengzhou Mining Machinery Co. Ltd is one of the leading mining machinery manufacturer

founded in 1956.

Read More →

Copyright©2015.Company name All rights reserved 豫ICP备11012423号-4