In the clay expanded aggregate industry, the common granulation methods are double roller extrusion granulation, drum granulation, kiln granulation, etc., among which roller extrusion granulation is the most common granulation method. There are two common structures of double roller granulator. The first one is that the reducer directly drives the fixed roller to rotate by the coupling. And the fixed roller drives the driven roller to rotate by friction. This structure is easy to maintain with smaller noise, but less finished products. The second one is that the chain drives two rollers to rotate at the same time with strong synchronicity. This structure is complex and difficult to maintain with bigger noise, but more finished products.

These two kinds of double roller granulators are suitable for handling materials with low stickiness and hardness. When it handles materials with high stickiness, the materials are easy to stick to the surface of the rollers. Or they can’t be demolded and granulated completely in the hole of roller surface. These materials can’t be demolded and granulated at one time. Then the materials sticky on the surface enter the roller extrusion position again and it will affect the next demolding and granulation at the corresponding hole position. It needs to be cleaned manually with less finished products.

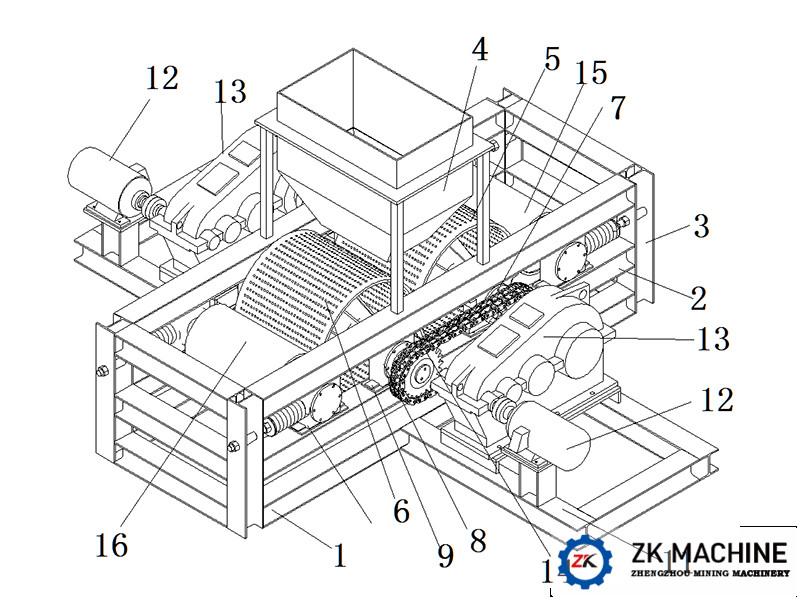

Our company has designed a new type of double roller granulator. It includes support frame, fixed roller and movable roller on the support frame. It also includes two auxiliary rollers which are rotated on the support frame. The outer surfaces of the first auxiliary roller and fixed roller are set to extrude the materials sticky on the outer surface of the fixed roller. The outer surfaces of the second auxiliary roller and the movable roller are set to extrude the materials sticky on the outer surface of the movable roller. There is also guide structure on the support frame. The elastic mechanism is connected between support frame and each auxiliary roller. The materials sticky on the mould could be transported to the active roller and corresponding auxiliary roller for the second extrusion with the rotation of the active roller. Finally it achieves to granular materials.

1-Support Frame;2-Middle Beam;3-Vertical Pillar;4-Feeding Hopper;5-Fixed Roller;6-Movable Roller;7-Fixed Bearing Pedestal;8-Movable Bearing Pedestal;9-Slide Guide;10- Clapboard;11-Supporting Seat;12-Drive Motor;13-Reducer;14-Chain;15-The First Auxiliary Roller;16-The Second Auxiliary Roller;17-Slide Guide;18-Screw Rod;19- Compressed Spring;20- Adjusting Nut;21-Fixed Nut;22-Auxiliary Roller Bearing Pedestal

Above is the introduction about twin drive double roller granulator. If you want to know more about the equipment, please consult the customer service of ZK CORP. ZK CORP is a professional manufacturer of mining machinery and equipment, with rich technical and project experience, Welcome to visit our factory!

Please input your inquiry in below form. We will reply you as soon as possible!

“The first-class professional design services High quality products.”

Henan Zhengzhou Mining Machinery Co. Ltd is one of the leading mining machinery manufacturer

founded in 1956.

Read More →

Copyright©2015.Company name All rights reserved 豫ICP备11012423号-4