Proposal generation

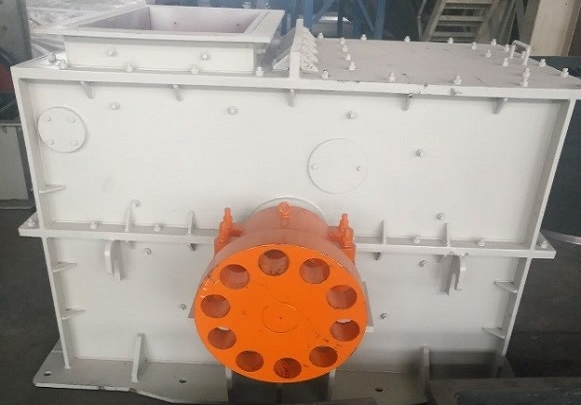

The customer is an American distributor, purchasing the PCH1010 ring hammer crusher, which is finally sold to the state-owned power plant of Columbia. The coal particle size is broken from less than 100mm to less than 20mm, and the capacity is 200tph.

Working principle

PCH1010 Ring Hammer Crusher is a kind of impact rotor crusher with a ring hammer. The ring hammer can not only rotate with the rotor but also rotate around the hammer pin. After the material enters the crusher, the ring rotates at a high speed in the crushing chamber Hammer the impact and broken, the broken material at the same time from the hammer to obtain kinetic energy, high-speed rushed to the crushing plate, by the second crushing, and then fell on the sieve plate, through the ring hammer shear, extrusion, grinding and materials collide with each other, the material is further broken, and discharged through the sieve outside. Discharge particle size adjustment is achieved by changing the specifications of the sieve, rotor and sieve spacing can be adjusted according to the need to adjust the device.

Structure and characteristics

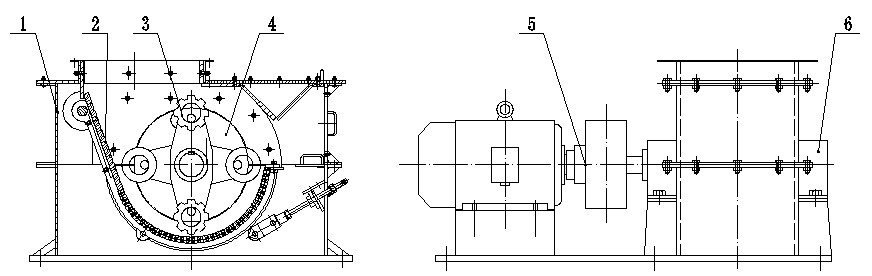

The ring hammer crusher is mainly composed of machine shell, sieve plate, hammer head, rotor disc, motor, coupling, bearing seat assembly and so on.

① machine shell

② sieve plate

③ hammer head

④ rotor disc

⑤ drive device

⑥ bearing seat assembly

Last Page:Ф900×1800 Wet Ball Mill for Russia Customer

Next Page:The achievement of ball mill to Pakistan

Please input your inquiry in below form. We will reply you as soon as possible

“The first-class professional design services High quality products.”