Hard tooth surface reducer and soft tooth surface reducer are two commonly used reducers. The specific differences are as follows:

1. Hard-tooth surface reducer gears are made of special steel, and after carburizing and quenching process, the surface hardness of the gear is above HRC45; soft surface reducer gears are mostly cut and polished from a whole piece of steel, and the gear hardness is low;

2. Hard-tooth surface reducer gears have high hardness, which can bear a lot of load and torque, and their wear resistance and life are better than those with soft tooth surfaces. Therefore, they are used on equipment with severe working conditions and heavy loads. , Such as cranes, mining equipment, large cement mixers, sewage treatment equipment, etc., must use hard tooth surface reducers to meet the requirements;

3. The soft tooth surface reducer is generally used on equipment with relatively small motor power because the gear hardness is not high and the load it can bear is low. The motor power of the soft tooth surface reducer generally does not exceed 3.7kw;

4. Hard tooth surface reducer has a long processing cycle and high cost; soft tooth surface reducer has a short production cycle, and the cost is much lower than that of hard tooth surface reducer;

5. The hardness of the output and input shaft of the hard tooth surface reducer is also much higher than that of the soft tooth surface reducer;

6. The input shaft speed of the hardened gear reducer is generally ≤1500r/min; the working environment temperature is minus 40 to 50 degrees, if it is lower than 0 degrees, the lubricating oil should be preheated to above 0 degrees before starting, both positive and negative In all directions.

7. Hard-tooth surface reducers generally adopt oil pool lubrication and natural cooling. When the thermal power cannot meet the requirements, circulating oil lubrication or air cooling or cooling coil cooling can be used.

Classification of hardened gear reducer

1. Hard-tooth surface gear reducers mainly include parallel shaft series and vertical shaft series. The vertical shaft series are not as stable as the parallel shaft series, so the parallel shaft series is preferred when space permits;

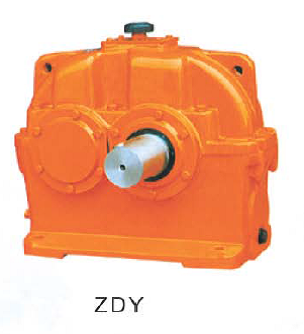

2. Parallel shaft series reducers are divided into four series according to national standards: ZDY (single-stage), ZLY (two-stage), ZSY (three-stage) and ZFY (four-stage).

Please input your inquiry in below form. We will reply you as soon as possible!

“The first-class professional design services High quality products.”

Henan Zhengzhou Mining Machinery Co. Ltd is one of the leading mining machinery manufacturer

founded in 1956.

Read More →

Copyright©2015.Company name All rights reserved 豫ICP备11012423号-4