Screw conveyor has the characteristics of compact structure, small cross-sectional area, light weight, good sealing performance, high conveying efficiency, flexible process layout, convenient installation, disassembly and movement, and safe operation. It is suitable for conveying various powdery, granular and small-block bulk materials, such as clay powder, coal powder, cement, sand, grains, small pieces of coal, pebbles and cast iron chips. It is not suitable for conveying materials with high viscosity, easy to agglomerate and easy to deteriorate. Screw conveyors have two installation methods: horizontal and inclined. It can be used in conjunction with other conveying working devices to complete operations such as collection, distribution, stirring, mixing, dehydration and unloading.

Domestic status:

my country's screw conveying devices are widely used in many industries, and their structural parameters and blade shapes are also more diverse; in terms of structural parameters, there are variable speed, variable pitch, variable shell diameter, variable shaft neck, large inclination, retractable and other screw conveying devices. In addition, there are shaftless screw conveyors, which are suitable for sludge and garbage treatment, and also suitable for conveying roughage such as crop straw.

Our products:

According to market needs and development trends, our company has deeply developed and upgraded screw conveyors. At present, it occupies a large share of the domestic and foreign markets for industrial material mixing and conveying and supporting production lines such as mining equipment, ceramsite sintering, and coal powder manufacturing. Among them, the LS series screw conveyor is a screw equipment improved by our company after digesting and absorbing similar products at home and abroad and optimizing the design. The LS series screw conveyor is a continuous conveying equipment without a flexible traction mechanism. It is generally used for short-distance continuous conveying of bulk materials in horizontal or slightly inclined directions (inclination angle β≤15°), and the materials can be mixed and stirred during the conveying process. The working environment temperature is -20~50℃, and the conveying material temperature is less than 200℃.

Application:

Its screw conveyor has the characteristics of compact structure, small cross-sectional area, light weight, good sealing performance, high conveying efficiency, flexible process layout, convenient installation, disassembly and movement, and safe operation. It is suitable for conveying various powdery, granular, and small-block bulk materials, such as clay powder, coal powder, cement, sand, grains, small-block coal, pebbles, and cast iron chips. It is not suitable for conveying materials with high viscosity, easy to agglomerate, and easy to deteriorate. The screw conveyor has two installation methods: horizontal and inclined. It can be used in conjunction with other conveying working devices to complete the operations of collection, distribution, stirring, mixing, dehydration, fixed-position batching, unloading, and stacking.

Structural features:

1. The head and tail bearing seats are arranged on the outside of the trough, which prevents dust from entering the bearings and makes installation and maintenance more convenient;

2. The optimized spiral blade solves the problem of easy material blockage at the discharge port;

3. The spiral main shaft adopts a variable diameter structure, which increases the volume at the hanging bearing, thereby reducing the contact between the hanging bearing and the material and reducing its wear;

4. The connection between the spiral shaft and the hanging bearing adopts embedded installation, and no axial movement is required during installation and disassembly, so maintenance and inspection are convenient;

5. The hanging bearing has an improved sealing and lubrication device, which effectively protects and lubricates the bearing and significantly improves its service life;

Working mode: The working principle of the screw conveyor is based on the rotation of the spiral blade to push the material forward. When the motor drives the spiral body to rotate, the material moves axially along the inner wall of the casing under the action of the spiral blade. This conveying method is continuous and stable, and can achieve efficient material transportation.

During the conveying process, the moving speed of the material is related to factors such as the speed of the spiral body and the pitch of the blade. Generally speaking, the speed of the screw is between 20 and 150r/min. The higher the speed, the faster the material is conveyed, but it will also increase energy consumption and equipment wear. The size of the pitch is selected according to the characteristics of the material and the conveying requirements. The common pitch range is between 100 and 500mm.

In addition, the screw conveyor can also realize bidirectional conveying of materials by changing the rotation direction of the spiral blade, which has great advantages in some occasions where the conveying direction needs to be flexibly adjusted.

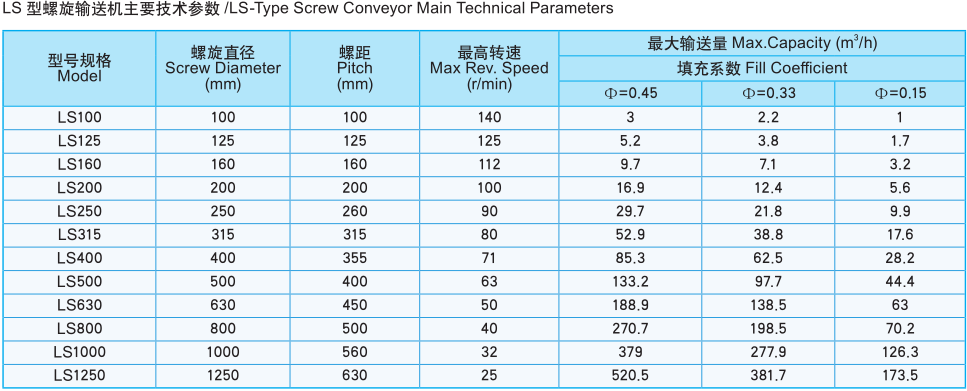

Technical parameters:

Note: When choosing a screw conveyor, multiple factors need to be considered comprehensively.

The first is the conveying capacity. The conveying capacity is one of the important indicators to measure the performance of the screw conveyor. It is related to the characteristics of the material, the diameter of the screw, the speed and other factors. Generally speaking, the conveying capacity of the screw conveyor is between 1 and 100m³/h. For example, for conveying powdery materials such as cement, when the screw diameter is 200mm and the speed is 60r/min, the conveying capacity can reach 5-10m³/h; while for conveying granular materials such as grains, under the same conditions, the conveying capacity may reach 10-20m³/h.

The second is the conveying distance. The conveying distance is also an important factor to be considered when selecting. As the conveying distance increases, the conveying resistance of the material will increase, and it is necessary to select a more powerful drive device and a more robust screw. Generally speaking, the horizontal conveying distance should not exceed 40m, and the vertical conveying distance should not exceed 8m. In addition, the characteristics of the material such as particle size, humidity, viscosity, etc. will also affect the selection of the screw conveyor. For materials with larger particle size, higher humidity or stronger viscosity, it is necessary to select a suitable spiral blade form and conveyor structure to ensure the smooth conveying of the material.

The screw conveyor plays an important role in the field of industrial material transportation with its unique composition structure, efficient working mode and wide applicability. When choosing a screw conveyor, enterprises should consider factors such as conveying volume, conveying distance, material characteristics, etc. according to their actual needs, and choose the most suitable equipment to improve production efficiency and reduce production costs.